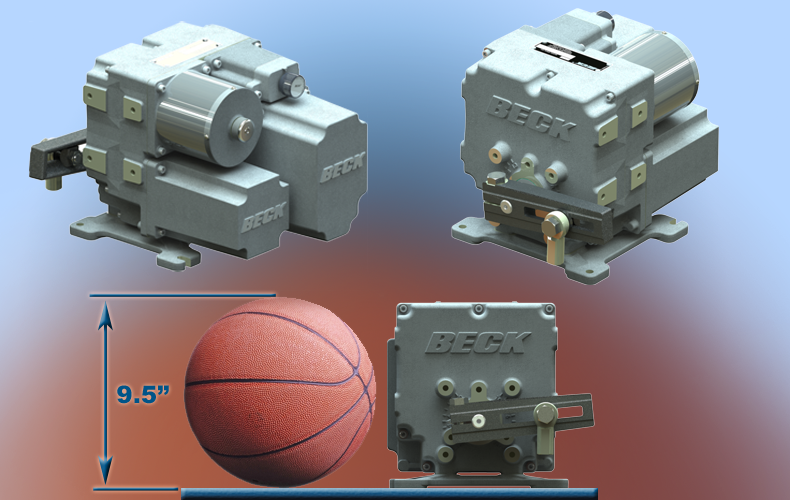

The ethanol blending process is a critical part of petrol terminal operation and has a significant impact on product quality, meeting environmental regulations and profitability. Optimising the processis very important, but does present some control challenges. For example,thermal expansion of petrol and ethanol do not occur at the same rate, and the blended mixture has to beisolated from water due to ethanol’s miscibility in water. For these reasons, many terminals blend in real time while loading directly into thetanker trucks, but the required control strategy does not allowmuch room for problems or inconsistencies. Getting the needed control begins with accurate, consistent and reliable valve actuation. Click the link to read more…