Model 29-100: Compact Electric Linear Actuator for High-Precision Valve Control

The Harold Beck Model 29-100 offers a compact yet powerful solution for automating small to medium-sized linear valves. With a thrust rating of 1,000 lbs, this actuator is specifically designed for applications where space is limited but precision cannot be compromised. The 29-100 replaces slow, maintenance-heavy pneumatic cylinders with a fast-acting electric drive that provides repeatable, accurate positioning to within 0.1% of span, drastically improving your process efficiency.

Every Model 29-100 is built with a focus on longevity and ease of use. The unit comes factory-calibrated to your specific valve requirements, allowing for immediate installation and startup. Its rugged, corrosion-resistant polyurethane coating and NEMA 4X rating ensure it performs reliably in everything from chemical processing to wastewater treatment. By integrating advanced digital diagnostics and a maintenance-free gear train, the 29-100 reduces total cost of ownership while maximizing valve life.

Core Benefits and Capabilities:

- • 1,000 lbs thrust capacity optimized for precision globe valve automation.

- • Fast stroke timing of 10 seconds per inch for rapid process response.

- • Contactless sensing technology eliminates mechanical wear and signal drift.

- • Low current draw design allows for operation via uninterruptible power supplies.

- • Built-in Tight-Seater mechanism ensures zero-leakage valve closure.

- • Universal mounting orientation allows for flexible installation in tight pipe galleries.

AVAILABLE THRUST AND TIMING COMBINATIONS FOR THE MODEL 29-100

(LBF)

(INCHES)

(SECONDS/INCH)

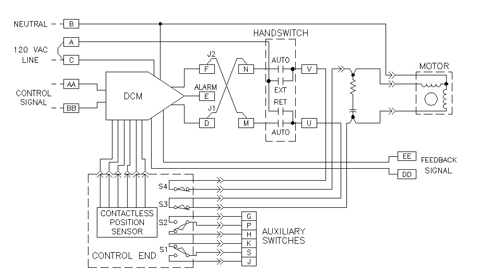

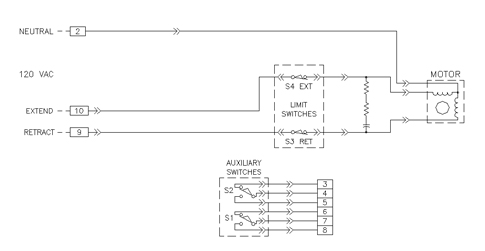

Beck’s DCM provides modulating control of the drive in response to standard control system signals.

Notable features include:

- Convenient user interface for calibration and drive status.

- HART® compatibility.

- Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train.

Beck’s patented CPS-4 technology has been providing reliable control feedback with infinite resolution in our products for many years.

- Utilizes a unique ferrite magnetic design with no contacting or wiping surfaces to wear or intermittently lose contact.

- The ferrite rotor is driven directly by the output shaft through anti-backlash gearing.

- A 4–20 mA position feedback signal is available for remote indication.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: