Model 29-600: Heavy-Duty Linear Valve Actuator with High-Thrust Precision

Maximize the performance of your globe valves and linear motion systems with the Harold Beck Model 29-600. Engineered for heavy-duty industrial service, this linear actuator provides exceptional thrust capabilities of up to 6,100 lbs, making it the ideal choice for high-pressure steam and fluid control. The 29-600 utilizes a precision ball screw and high-efficiency spur gears to deliver smooth, responsive linear movement that ensures your valves seat tightly and modulate with unmatched accuracy.

The Model 29-600 is equipped with the proprietary Tight-Seater device, ensuring positive valve seating at the closed position to prevent costly leakage and energy loss. Its advanced electronics package includes a Digital Control Module with HART protocol, providing real-time diagnostics and easy field calibration. With a rugged, dust-tight enclosure and a motor that won't coast or overshoot, the 29-600 delivers the "set it and forget it" reliability required for high-uptime industrial automation.

Key Technical Advantages:

- • Heavy-duty thrust ratings up to 6,100 lbs for critical high-pressure valve applications.

- • Precision ball screw design for long-life performance and minimal mechanical wear.

- • Integrated Tight-Seater technology for guaranteed positive valve shutoff.

- • Continuous-duty motor prevents overheating during constant modulation cycles.

- • Self-locking mechanism instantly holds position upon de-energization to prevent back-driving.

- • Dual-compartment NEMA 4X housing protects electronics from moisture and industrial contaminants.

AVAILABLE THRUST AND TIMING COMBINATIONS FOR THE MODEL 29-600

(LBF)

(INCHES)

(SECONDS/INCH)

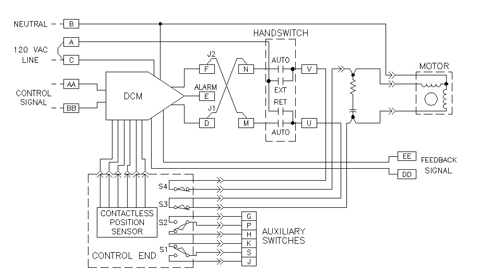

Beck’s DCM provides modulating control of the drive in response to standard control system signals.

Notable features include:

- Convenient user interface for calibration and drive status.

- HART® compatibility.

- Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train.

Beck’s patented CPS-4 technology has been providing reliable control feedback with infinite resolution in our products for many years.

- Utilizes a unique ferrite magnetic design with no contacting or wiping surfaces to wear or intermittently lose contact.

- The ferrite rotor is driven directly by the output shaft through anti-backlash gearing.

- A 4–20 mA position feedback signal is available for remote indication.

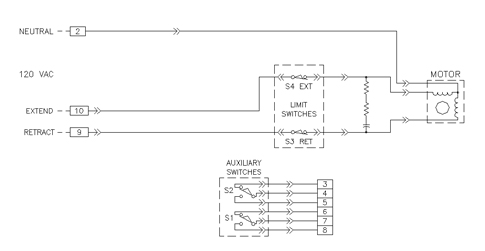

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: